Correct Mounting Of Tyres

1. The valve core should be replaced and inflated to the recommended pressure; the valve cap must be screwed post this.

2. Ensure that the inflation is done without the valve core and without any interruption till the beads are well seated on the rim

3. Valve must be replaced during tyre change

4. Ensure total compliance with tyre and motorcycle manufacturer’s specifications

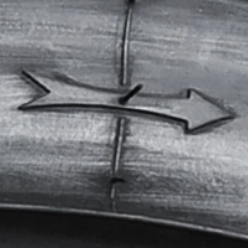

5. The rolling direction of the tyre is denoted by an arrow on one side of the sidewall

6. Ensure that the rim band is installed in spoke-based wheels; this prevents the inner tube from being damaged by spokes.

7. The rim must be free of rust, clean and in good condition

8. Don't mount tyres with petroleum-based lubricants. Avoid improper hand tools to mount tires.

9. Inspect and clean your tyre thoroughly

10. The inner parts of the rim and the bead of the tyre must be lubricated on both sides, with a suitable lubricant. Do not use grease or mobil oil. Use only liquid soap.

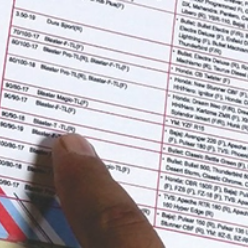

11. Tyre and wheel type must always match. Never fit a tubeless (TL) tyre on a tube-type (TT) wheel

12. Inflate the tube slightly before inserting it into the tyre envelope.

13. Perform bead to rim mounting using adequate levers. Finish this process just ahead of the wall

14. Use a new inner tube for assured safety

15. For proper bead seating, inflate up to 3.5 bar (51 psi)

16. Always use a vegetable-based lubricant for bead lubrication. Use new valves in tubeless and new lube in tube-type with new tyre.